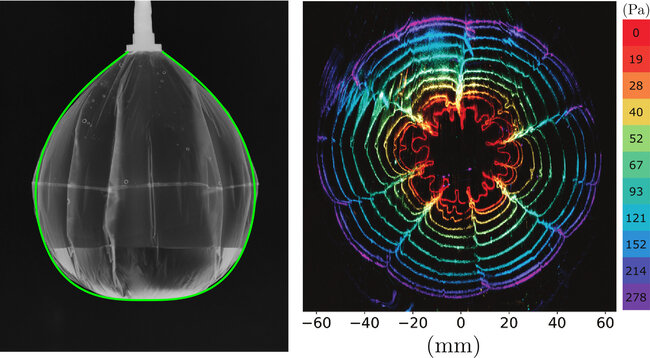

Although thin films are typically manufactured in planar sheets or rolls, they are often forced into three-dimensional (3D) shapes, producing a plethora of structures across multiple length scales. To understand this complex response, previous studies have either focused on the overall gross shape or the small-scale buckling that decorates it. However, it remains unclear how the selection of an overall shape constrains the behavior of smaller-scale wrinkles or folds. We have investigated a prototypical system consisting of a thin-membraned balloon that is partially filled with water and pressurized with air. We have shown that a geometrical, which considers the sheet as inextensible yet free to compress, predicts the overall shape of the balloon. We have proposed a quasi-two-dimensional model that captures an array of features seen in the experiments, from the shapes of individual folds to how the membrane morphology changes with pressure.

Although thin films are typically manufactured in planar sheets or rolls, they are often forced into three-dimensional (3D) shapes, producing a plethora of structures across multiple length scales. To understand this complex response, previous studies have either focused on the overall gross shape or the small-scale buckling that decorates it. However, it remains unclear how the selection of an overall shape constrains the behavior of smaller-scale wrinkles or folds. We have investigated a prototypical system consisting of a thin-membraned balloon that is partially filled with water and pressurized with air. We have shown that a geometrical, which considers the sheet as inextensible yet free to compress, predicts the overall shape of the balloon. We have proposed a quasi-two-dimensional model that captures an array of features seen in the experiments, from the shapes of individual folds to how the membrane morphology changes with pressure.

Authors: Mengfei He, Vincent Démery and Joseph D. Paulsen

Publication: PNAS 2023, Vol. 120 No. 11 e2216786120

https://doi.org/10.1073/pnas.2216786120